Settings

nreg <- 5

# nreg <- 32 # alternative number of regions

# region names where offshore regions (if any) associated with closest land-region:

regN <- glue("reg{nreg}")

# offshore regions have distinct names:

regN_off <- glue("reg{nreg}_off") The goal of carbon capture, utilization and storage (CCS or CCUS) technologies is to reduce carbon emissions from fuels combustion and industrial processes. The emissions are captured, transported, and stored in geological formations, or used in other industrial processes. The captured CO2 potentially can be used in enhanced oil recovery (EOR), or in the production of chemicals, fuels, and materials. However, the current status of utilization is limited and the main focus is on the storage of CO2 in geological formations.

Carbon sink potential

The potential of geological storage varies by region and depends on the availability of suitable geological formations, the distance to the sources of CO2, and the existing infrastructure. Here we use an estimated value [LINK] of CCS storage potential in saline aquifers and basalt formations by region.

# Data on the potential of CO2 storage in geological formations

# NOTE: the original data is by 5 regions, disaggregation is used for higher nreg

ccs_reserve <- get_ideea_data(name = "ccs_r5", nreg = nreg)

# Declaration of domestic carbon sink resources

# the objects is declared in `energy` document and saved in ideea_modules$energy

# here we import saved objects for the requested number of regions

# A commodity to represent the storage of CO2

CO2SINK <- ideea_modules$energy[[regN]]$CO2SINK

# Permanent geological carbon storage (saline aquifers and basalt) potential

RES_CO2SINK <- ideea_modules$energy[[regN]]$RES_CO2SINK

# Declaration of captured CO2 "commodity"

CCSCO2 <- newCommodity(

name = "CCSCO2",

desc = "Captured CO2, kt",

unit = "kt",

#slice = "ANNUAL", deprecated

timeframe = "ANNUAL"

)

# Declaration of composite GHG

GHG <- newCommodity(

name = "GHG",

desc = "Greenhouse gas emissions, Mt",

unit = "Mt",

agg = data.frame(

comm = c("CO2", "CCSCO2"),

unit = "kt",

agg = c(1e3, -1e3)

),

misc = list(

info = c("GHG is a composite commodity that aggregates CO2 and CCSCO2 with",

"specified weights (in @agg$agg)")

)

)@emis slot of every commodity. For example, the

emis slot of coal commodity COA@emis is set

to:

| comm | unit | emis |

|---|---|---|

| CO2 | kt/GWh | 0.33 |

GAS@emis):

| comm | unit | emis |

|---|---|---|

| CO2 | kt/GWh | 0.18 |

In the current settings, the emis parameter in the

@emis slot represents the kt of CO2 emissions

per GWh of fuel use (by default, all energy is measured in

GWh in IDEEA model).

When the fuels are used in power plants, the emissions are calculated

based on the fuel use, the emission factors, and the

combustion parameter in technology class (slot

@input) which is set to 1 by default.

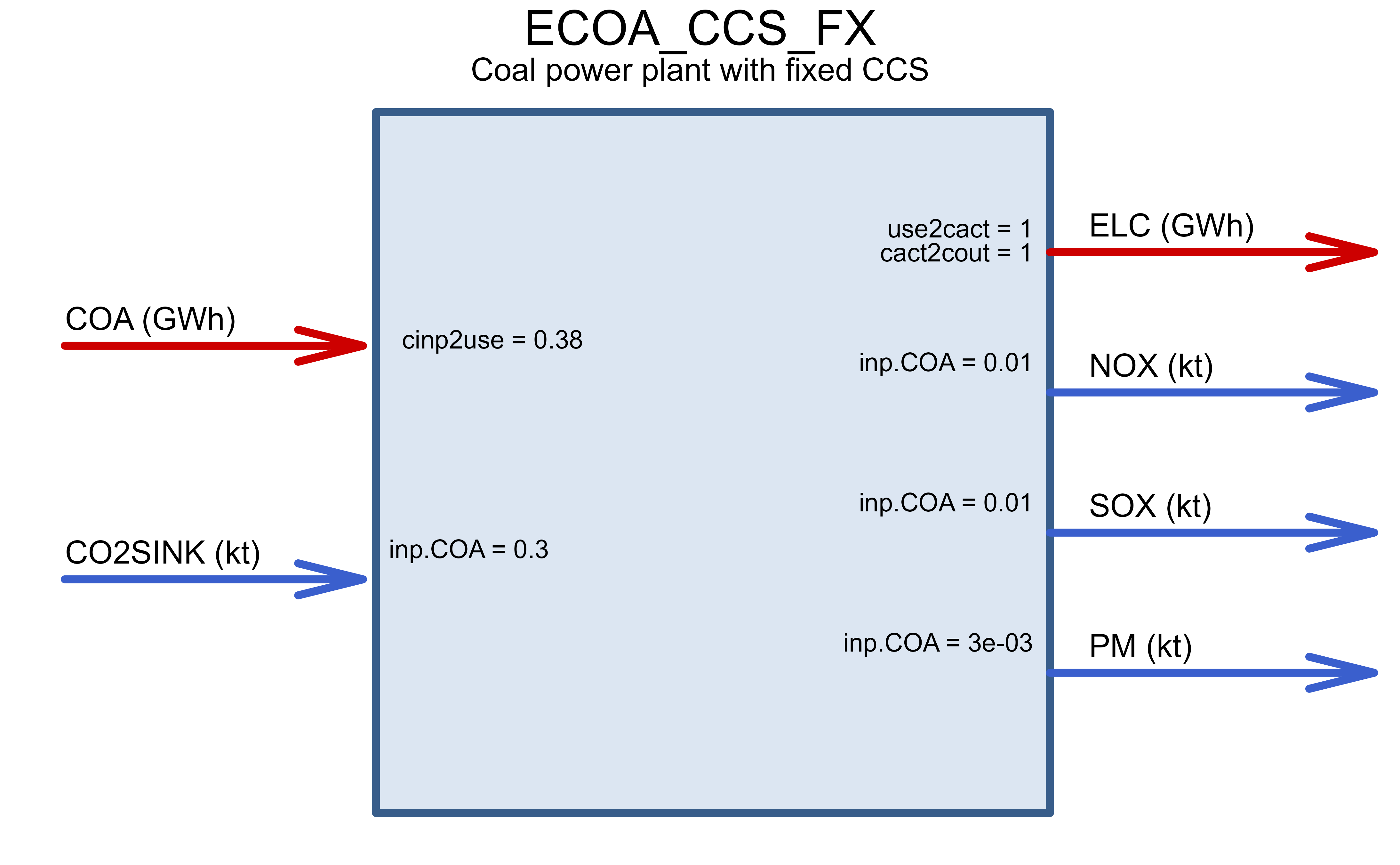

CCS with fixed capture rate

The simplest way to reduce CO2 emissions of a power generation in the

model is not adjust the combustion parameter by the CCS

capture rate. The efficiency and costs associated with CCS must be also

adjusted accordingly. Bellow we “upgrade” a coal power plant from IDEEA

model dataset with CCS technology.

Coal power plant with CCS

COA <- ideea_modules$energy[[regN]]$COA

ECOA_prototype <- ideea_modules$techs$ECOAULT@data$ECOAULT_2030

ECOA_prototype@input

#> comm unit group combustion

#> 1 COA GWh <NA> NAIf the combustion parameter is not set (NA or

empty), the default value is used (1). For

simplicity, we assume that the plant with CCS has 90% capture rate, 10%

efficiency loss, and 50% capital, fixed, and variable costs increase.

The prototype of the CCS technology is shown below.

# no CCS

ECOA_prototype@input

#> comm unit group combustion

#> 1 COA GWh <NA> NA

# with CCS

ECOA_CCS_FX <- update(

ECOA_prototype,

name = "ECOA_CCS_FX",

desc = "Coal power plant with fixed CCS",

input = list(comm = "COA", combustion = 0.1, unit = "GWh")

)

# Efficiency, no CCS

kableExtra::kable(

select(ECOA_prototype@ceff, region, year, comm, cinp2use)

)| region | year | comm | cinp2use |

|---|---|---|---|

| NA | NA | COA | 0.418 |

# Efficiency, with CCS (~10% loss)

ECOA_CCS_FX@ceff$cinp2use <- ECOA_prototype@ceff$cinp2use * 0.9

# Costs (~50% up)

ECOA_CCS_FX@invcost$invcost <- ECOA_prototype@invcost$invcost * 1.5

ECOA_CCS_FX@fixom$fixom <- ECOA_prototype@fixom$fixom * 1.5

ECOA_CCS_FX@varom$varom <- ECOA_prototype@varom$varom * 1.5

# extend the availability window of the technology on the market

ECOA_CCS_FX@end$end <- 2100Finally, since the sequestration potential is also limited, we can

track the utilization of carbon storage by specifying input commodity

(CO2SINK) and in the aeff slot of the

technology. The CO2SINK commodity is used to track the

amount of CO2 stored in geological formations. We can also reduce the

emissions of conventional pollutants (NOX, SOX, PM) by the same

percentage as the CO2 emissions, specified in the auxiliary commodities

and efficiency slots @aux and @aeff.

# no CCS

ECOA_prototype@aux

#> acomm unit

#> 1 NOX kt

#> 2 SOX kt

#> 3 PM kt

ECOA_prototype@aeff |> select(acomm, comm, cinp2aout, cinp2ainp)

#> acomm comm cinp2aout cinp2ainp

#> 1 SOX COA 0.10 NA

#> 2 NOX COA 0.10 NA

#> 3 PM COA 0.03 NA

# with CCS

ECOA_CCS_FX <- update(

ECOA_CCS_FX,

aux = data.frame(

acomm = c("NOX", "SOX", "PM", "CO2SINK"),

unit = c("kt", "kt", "kt", "kt")

),

aeff = data.frame(

acomm = c("CO2SINK", ECOA_prototype@aeff$acomm),

comm = c("COA", "COA", "COA", "COA"),

cinp2ainp = c(COA@emis$emis * 0.9, NA, NA, NA), # 90% capture rate

cinp2aout = c(NA, ECOA_prototype@aeff$cinp2aout * 0.1)

),

varom = data.frame(

acomm = "CO2SINK",

cvarom = convert(120.1, "USD/t", "cr.₹/kt") # ~0.1 cr.₹/kt

)

)

draw(ECOA_CCS_FX)

If CO2SINK is used, the commodity and it’s resource must

be added to the model.

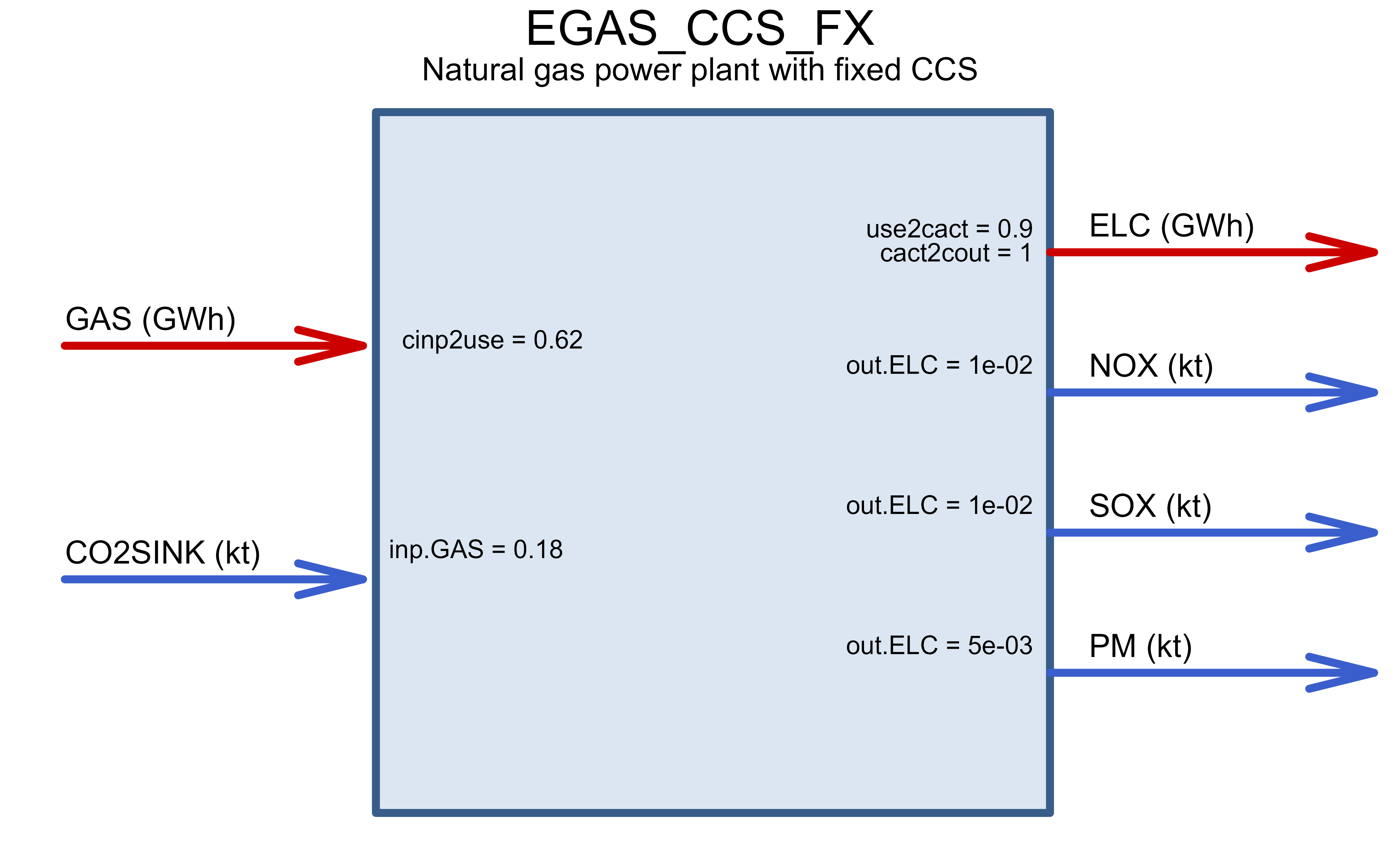

Gas power plant with CCS

Similarly we can add CCS to natural gas and biomass-powered plants. Instead of updating the existing technology without CCS, we design the technology from scratch to demonstrate a technology-building process.

GAS <- ideea_modules$energy[[regN]]$GAS

EGAS_prototype <- ideea_modules$techs$ENGCC$ENGCC_2030

EGAS_CCS_FX <- newTechnology(

name = "EGAS_CCS_FX",

desc = "Natural gas power plant with fixed CCS",

input = list(

comm = "GAS",

unit = "GWh",

combustion = .1 # 10% of emissions are not captured by CCS

),

output = data.frame(

comm = "ELC",

unit = c("GWh")

),

aux = data.frame(

acomm = c("NOX", "SOX", "PM", "CO2SINK", "CO2"),

unit = c("kt", "kt", "kt", "kt", "kt")

),

ceff = list(

cinp2use = c(EGAS_prototype@ceff$cinp2use, NA), # 62% efficiency w/o CCS

use2cact = c(NA, .9), # 10% efficiency loss with CCS

comm = c("GAS", "ELC")

),

aeff = data.frame(

acomm = c("CO2SINK", "NOX", "SOX", "PM"),

comm = c("GAS", rep("ELC", 3)),

cinp2ainp = c(GAS@emis$emis[1], rep(NA, 3)),

cout2aout = c(NA, .01, .01, .005) # arbitrary

),

olife = list(olife = 40),

invcost = data.frame(

invcost = 1.5 * EGAS_prototype@invcost$invcost

),

fixom = data.frame(

fixom = 1.5 * EGAS_prototype@fixom$fixom

),

# variable costs are assigned in the CO2SINK supply,

# here is an alternative formulation with the same effect:

# varom = data.frame(

# acomm = "CO2SINK",

# cvarom = convert(12.1, "USD/t", "cr.₹/kt") # ~0.1 cr.₹/kt

# ),

start = list(start = 2025)

# end = list(end = 2060),

)

draw(EGAS_CCS_FX)

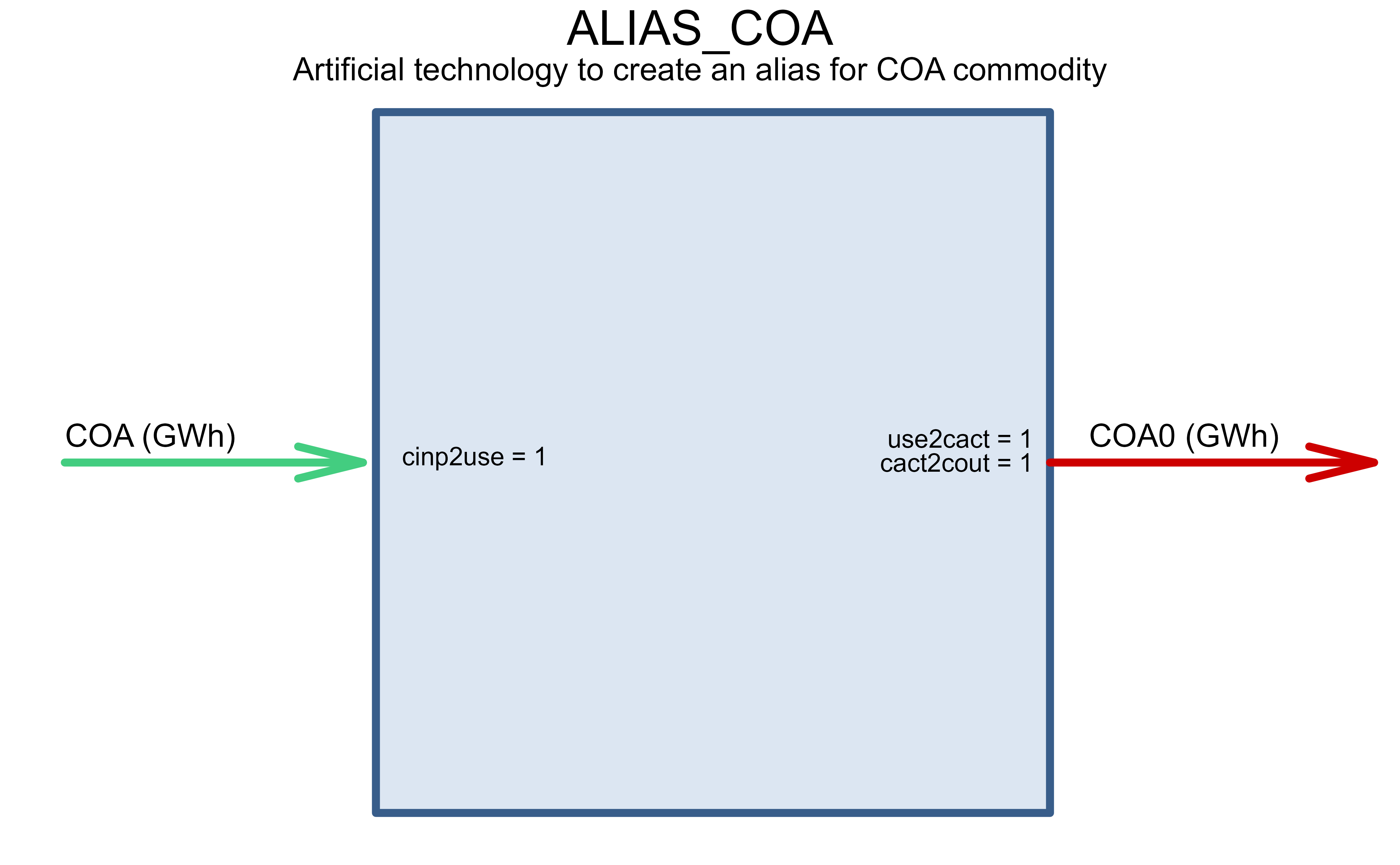

CCS with flexible capture rate

The example above assumes that once installed, CCS will be operated at maximum removal capacity. This setting will probably fit most decarbonization studies, but in some cases it might be helpful to have an optional use of CCS technology. For example, the technology can be designed to operate at a lower capture rate, depending on the strength of the carbon control policy, carbon price or the market.

The following case demonstrates an alternative way to design a CCS

technology with a flexible capture rate. To make the operation rate

flexible, we introduce an alternative fuel input (COA_CCS

or GAS_CCS) and define a group of fuel inputs with

different capture rates (set via combistion parameter as

before).

# Alias commodity for coal (COA) with zero emissions

COA0 <- COA |>

update(

name = "COA0",

desc = "Alias for COA"

)

ALIAS_COA <- newTechnology(

name = "ALIAS_COA",

desc = "Artificial technology to create an alias for COA commodity",

input = list(

comm = "COA",

unit = "GWh",

combustion = 0

),

output = data.frame(

comm = "COA0",

unit = "GWh"

),

cap2act = 1e12, # capable to convert GWh a year

capacity = list(stock = 1), # pre-defined capacity to reduce the model dimension

end = list(end = 2000) #

)

draw(ALIAS_COA)

This “alias” commodity does not require a new resource, it’s supply

will be defined and bounded by the supply of the original commodity via

the ALIAS_COA technology which has no costs, therefore will

not affect the model’s objective, but will be responsible for the supply

of the COA0 commodity, “made” of the COA

commodity.

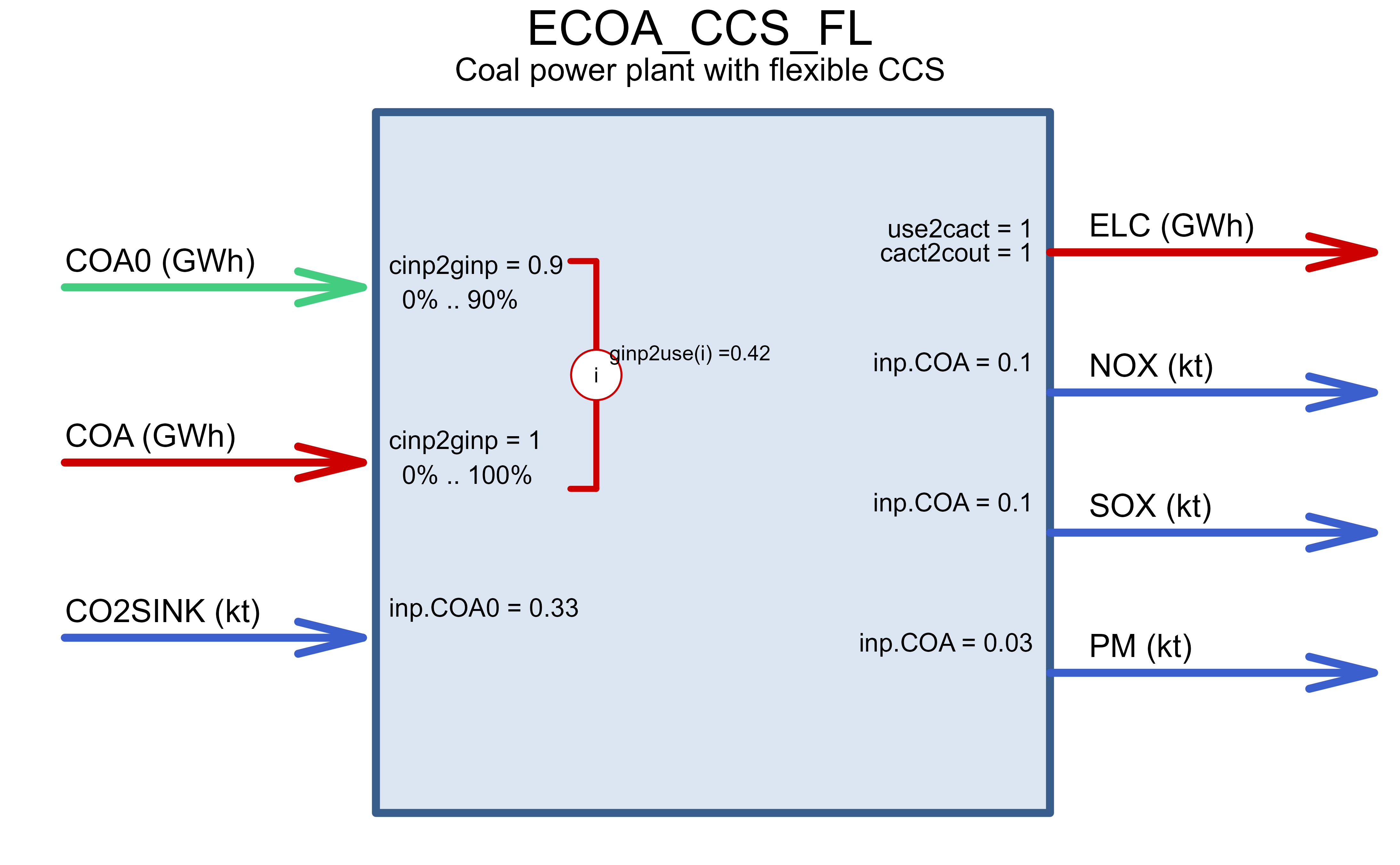

Coal power plant with flexible CCS

The key difference of the flexible CCS technology vs. fixed described

above is the introduction of the group parameter in the

input and ceff slots. The group

parameter is used to define a group of commodities with different

capture rates. The ceff slot is used to define the

efficiency loss when the alternative fuel is used

(cinp2ginp) and the share of each commodity in the group to

define the maximum capture rate (share.up).

ECOA_CCS_FL <- ECOA_CCS_FX |>

update(

name = "ECOA_CCS_FL",

desc = "Coal power plant with flexible CCS",

input = list(

comm = c("COA", "COA0"),

unit = c("GWh", "GWh"),

group = c("i", "i"), # any group name

combustion = c(1, 0) # 10% of emissions are not captured by CCS

),

geff = list(

group = "i",

ginp2use = ECOA_prototype@ceff$cinp2use[1]

),

ceff = list(

comm = c("COA", "COA0"),

cinp2ginp = c(1, .9), # efficiency loss when COA is used

share.up = c(1, .9) # max share of each commodity in the group

),

# auxiliary inputs/outputs does not require adjustment for CCS

# since it is defined by CCS utilization (COA vs COA0)

aeff = data.frame(

acomm = c("CO2SINK", ECOA_prototype@aeff$acomm),

comm = c("COA0", "COA", "COA", "COA"),

cinp2ainp = c(COA@emis$emis, NA, NA, NA), # 90% capture rate

cinp2aout = c(NA, ECOA_prototype@aeff$cinp2aout)

)

)

draw(ECOA_CCS_FL)

This technology is designed to operate from 0% to 90% capture rate instead of fixed 90% in the fixed rate example.

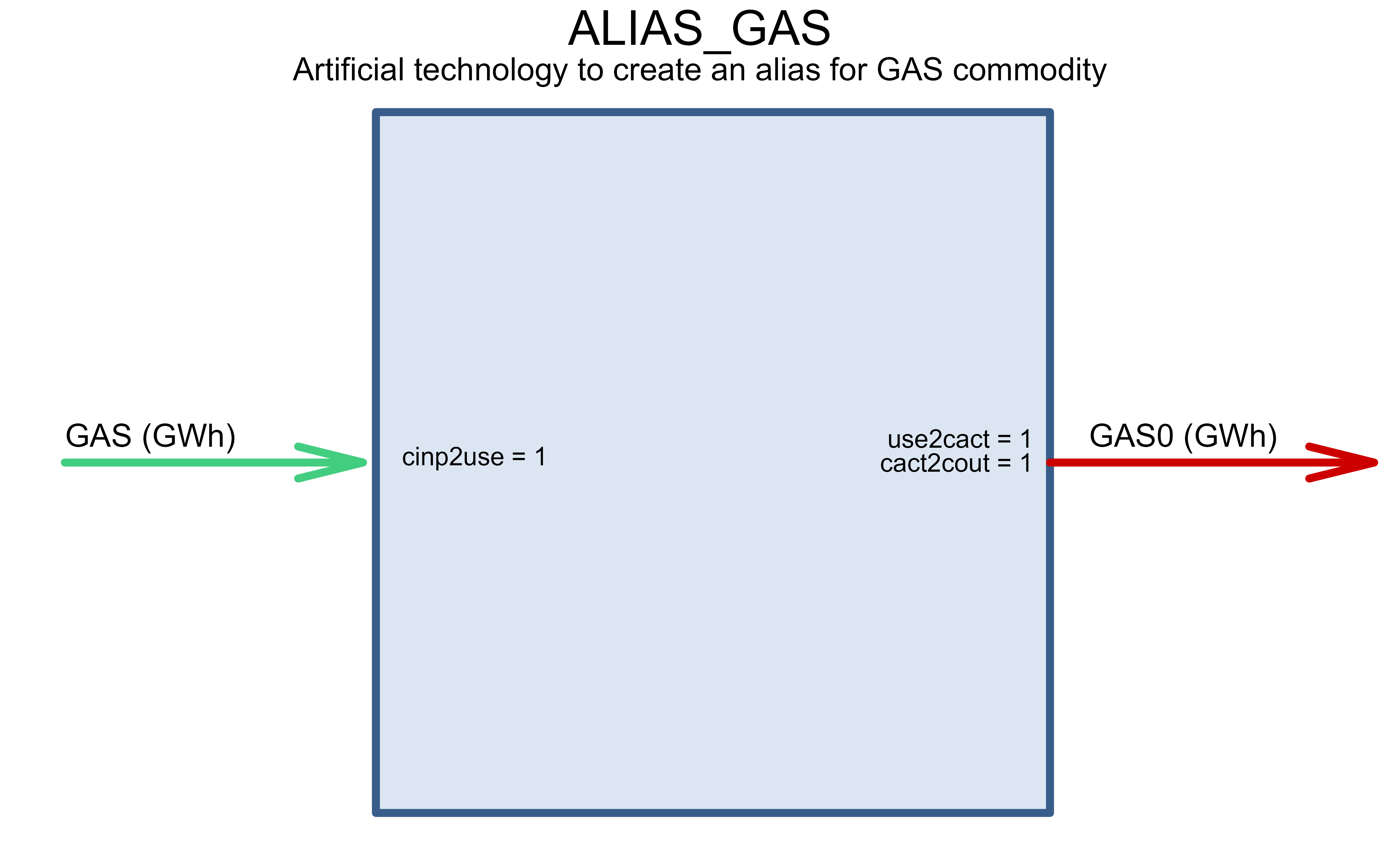

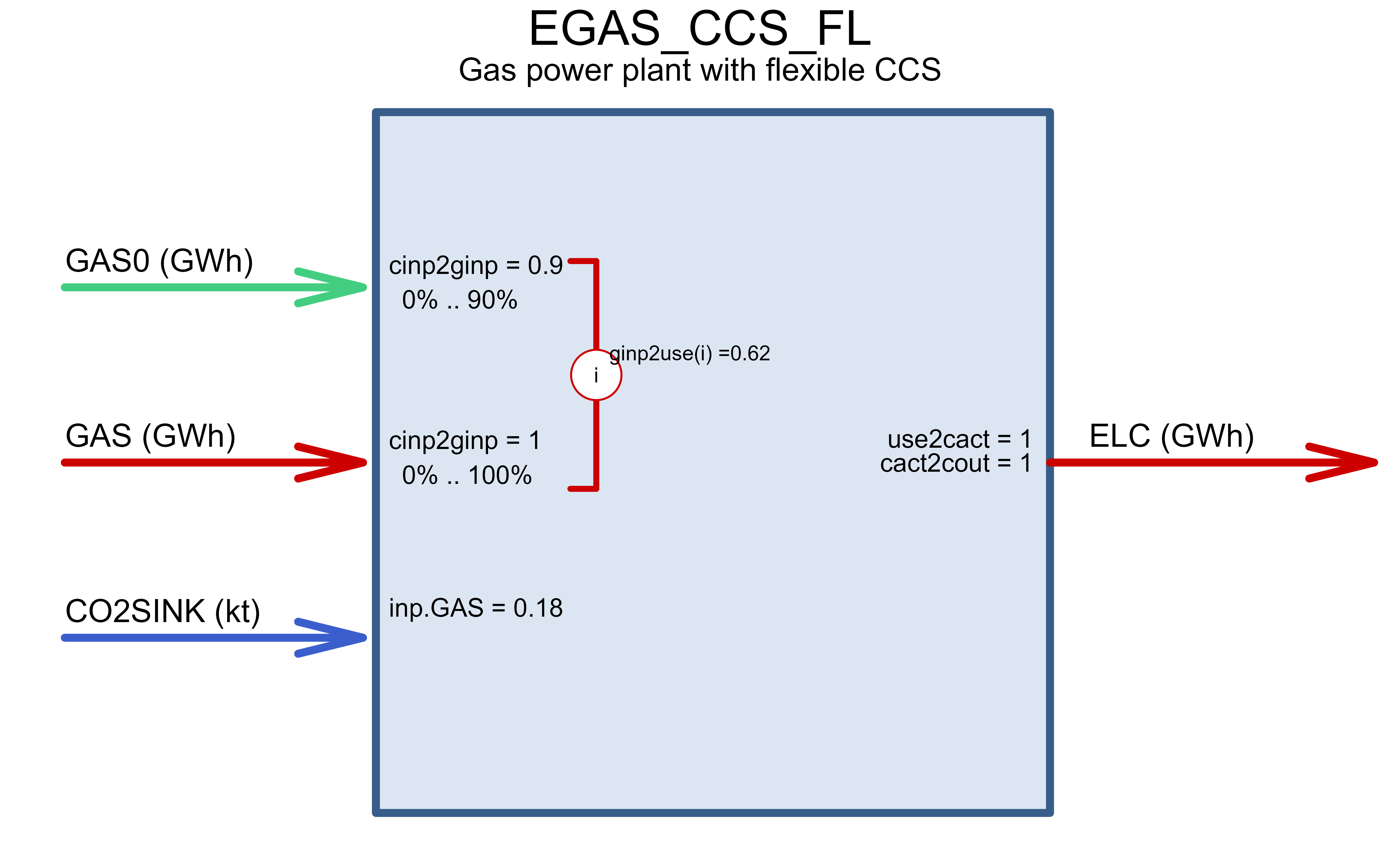

Gas power plant with flexible CCS

The same approach can be applied to the gas technology.

GAS0 <- GAS |>

update(

name = "GAS0",

desc = "Alias for GAS"

)

ALIAS_GAS <- newTechnology(

name = "ALIAS_GAS",

desc = "Artificial technology to create an alias for GAS commodity",

input = list(

comm = "GAS",

unit = "GWh",

combustion = 0

),

output = data.frame(

comm = "GAS0",

unit = "GWh"

),

cap2act = 1e12, # capable to convert GWh a year

capacity = list(stock = 1), # pre-defined capacity to reduce the model dimension

end = list(end = 2000) #

)

draw(ALIAS_GAS)

EGAS_CCS_FL <- EGAS_CCS_FX |>

update(

name = "EGAS_CCS_FL",

desc = "Gas power plant with flexible CCS",

input = list(

comm = c("GAS", "GAS0"),

unit = c("GWh", "GWh"),

group = c("i", "i"), # any group name

combustion = c(1, 0) # 10% of emissions are not captured by CCS

),

geff = list(

group = "i",

ginp2use = EGAS_prototype@ceff$cinp2use[1]

),

ceff = list(

comm = c("GAS", "GAS0"),

cinp2ginp = c(1, .9), # efficiency loss when COA is used

share.up = c(1, .9) # max share of each commodity in the group

),

aeff = data.frame(

acomm = c("CO2SINK", EGAS_prototype@aeff$acomm),

comm = c("GAS", "GAS", "GAS", "GAS"),

cinp2ainp = c(GAS@emis$emis, NA, NA, NA), # 90% capture rate

cinp2aout = c(NA, EGAS_prototype@aeff$cinp2aout)

)

)

draw(EGAS_CCS_FL)

References

Carbon Capture, Utilization and Storage (CCUS) Policy Framework and

its Deployment Mechanism in India Utilization and Storage (CCUS)

https://www.niti.gov.in/sites/default/files/2022-11/CCUS-Report.pdf